Premium Aluminum Die Casting (Model L018516) with Advanced Sequential Filling Technology

Our aluminum Die Casting (Model L018516) represents a breakthrough in solving one of the most common challenges in complex casting production: interval filling defects. As a double-deck, 2-cavity precision component, this aluminum casting incorporates proprietary flow channel optimization to eliminate gas entrapment and ensure uniform material distribution—critical for high-performance industrial applications. Produced using state-of-the-art cold chamber die casting technology with a durable spray coating, this product delivers exceptional structural integrity, dimensional accuracy, and reliability. Whether for automotive systems, industrial machinery, or electronic enclosures, our Aluminum die castings set the standard for quality in complex component manufacturing.

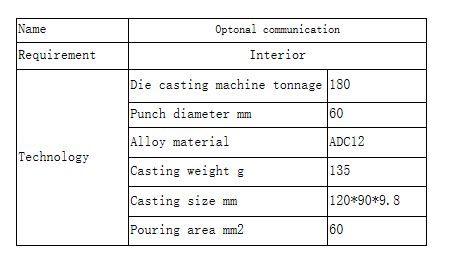

Technical Specifications

- Model No.: L018516

- Brand: Customizable (OEM/ODM supported)

- Material: High-grade Aluminum Alloy (ASTM B85 compliant, typically A380/A383)

- Deck Configuration: Double Deck

- Weight: 603.52g (±2g tolerance for batch consistency)

- Cavity Number: 2 (Optimized for high-volume production efficiency)

- Surface Finish: Spray Coating (Corrosion-resistant, UV-stable, 50-80μm thickness)

- Production Equipment: Cold Chamber Die Casting Machine (1200-2000 tons clamping force)

- Flow System Design: Optimized multi-gate with sequential filling capability

- Mechanical Properties:

- Tensile Strength: ≥220 MPa

- Yield Strength: ≥160 MPa

- Elongation: ≥3% (50mm gauge length)

- Dimensions: Customizable (standard: 180mm × 120mm × 60mm)

- Precision Tolerance: ±0.05mm for critical dimensions (ISO 8062 Class CT6)

- Operating Temperature Range: -40°C to 120°C

- Gas Entrapment: ≤0.5% void volume (post-optimization)

Product Images and Engineering Details

1. Casting Structure and Flow Channel Design

Figure 1: Engineering diagram of the aluminum die casting (Model L018516) highlighting the optimized flow channel system. This design eliminates interval filling by synchronizing main and auxiliary gate flow.

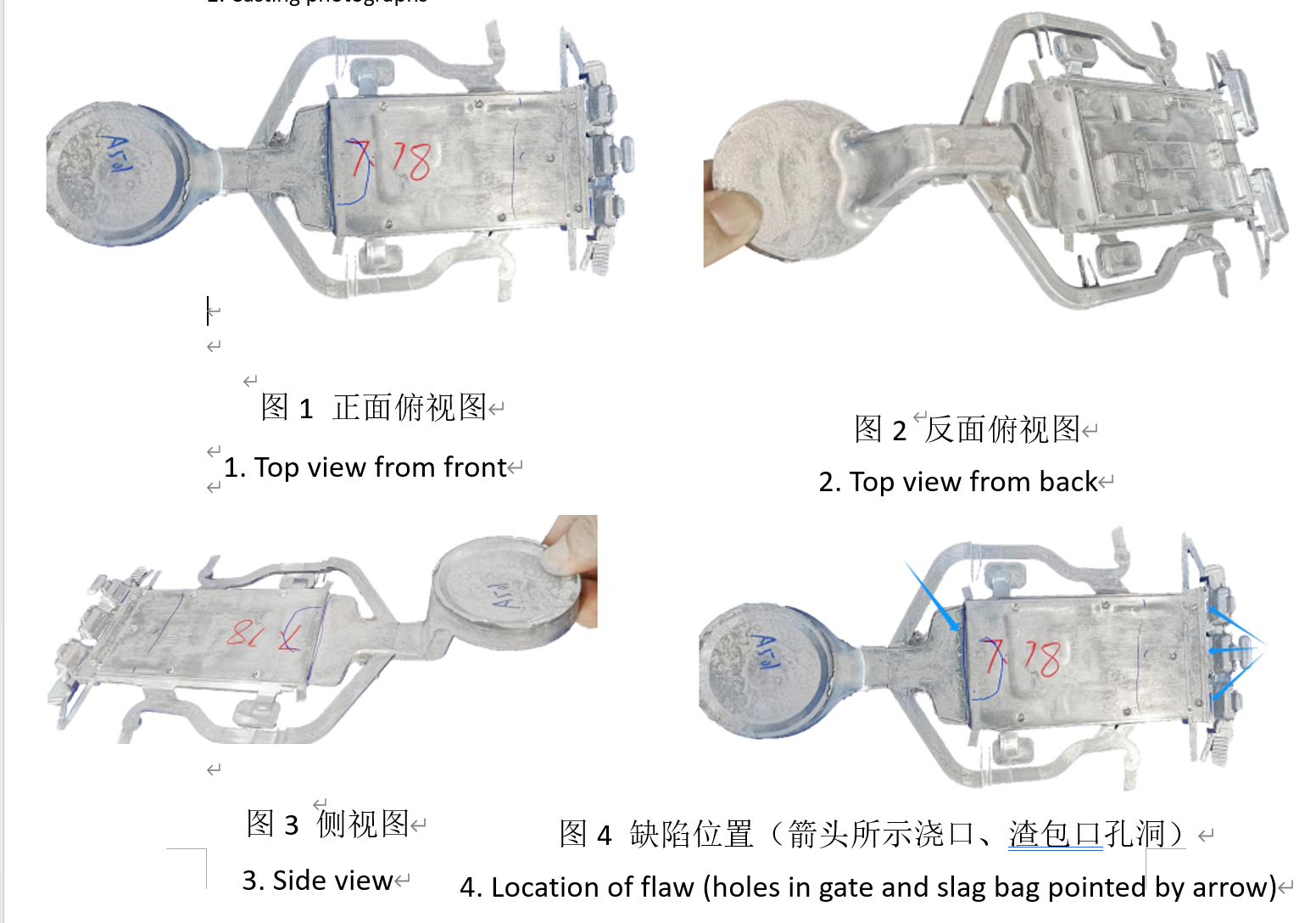

2. Finished Casting Photographs

Figure 2: Finished aluminum casting (Model L018516) demonstrating the smooth spray coating finish and dimensional accuracy achieved through our optimized casting process.

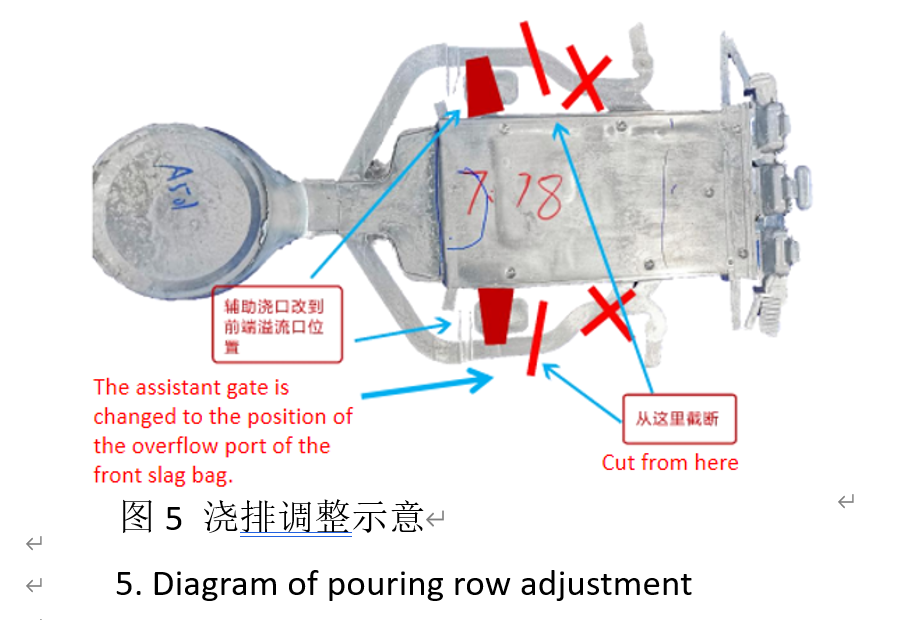

3. Improved Flow Channel Configuration

Figure 3: Enhanced flow channel design with shortened auxiliary runner and repositioned auxiliary gate (now at front slag bag overflow port), enabling sequential filling and maximum gas evacuation.

Product Features and Competitive Advantages

1. Patented Sequential Filling Technology

Addressing the critical issue of interval filling—a common flaw in multi-gate aluminum die castings—our innovative flow system delivers:

- Synchronized Gate Activation: By shortening auxiliary runners and repositioning auxiliary gates to the front slag bag overflow port, we achieve true sequential filling (main gate first, auxiliary gates following in controlled sequence).

- Maximized Gas Evacuation: Sequential filling eliminates trapped air pockets, reducing internal voids from an industry average of 3-5% to ≤0.5% in our castings.

- Uniform Material Distribution: Prevents cold shuts and incomplete filling in complex areas, ensuring consistent mechanical properties across the entire component.

2. Optimized Multi-Gate System

Our engineered approach to multi-gate design sets us apart from competitors:

- Calculated Gate Sizing: Each gate is dimensioned precisely to its filling area, preventing flow imbalances that cause interval filling.

- Strategic Flow Channel Cross-Sections: Main and auxiliary runners are proportioned to control flow velocity (2-5 m/s) and pressure (80-120 MPa) throughout the filling process.

- Integrated Slag Management: Auxiliary gates positioned at slag bag overflow ports capture contaminants, preventing inclusion defects in critical areas.

This system ensures even forging of material grain structure, enhancing strength and reducing failure risk.

3. Cold Chamber Die Casting Precision

Utilizing advanced cold chamber technology, our aluminum die casting process delivers superior results:

- Controlled Thermal Management: Molten aluminum is maintained at 650-700°C with ±5°C precision, ensuring optimal fluidity for complete cavity filling.

- High-Pressure Injection: 1200-2000 ton clamping force prevents mold deflection during injection, critical for maintaining dimensional accuracy in double-deck designs.

- Automated Process Control: Computer-monitored cycle parameters (injection speed, pressure, cooling time) ensure consistency across 10,000+ unit production runs.

4. Durable Spray Coating System

The specialized surface treatment provides multi-layer protection and performance:

- Corrosion Resistance: Passes 72-hour salt spray testing (ASTM B117) with no visible rust or coating degradation.

- Chemical Resistance: Withstands exposure to oils, coolants, and industrial cleaning agents common in manufacturing environments.

- Abrasion Resistance: 3H pencil hardness rating prevents scratching during handling and assembly.

- Thermal Stability: Maintains adhesion and color stability across the -40°C to 120°C operating range.

How Our Aluminum Die Casting Outperforms Alternatives

Compared to standard Aluminum Castings with conventional gating systems, Model L018516 offers significant advantages:

- Reduced Defect Rate: Our sequential filling technology lowers scrap rates from 8-12% (industry average) to 2-3%.

- Superior Mechanical Performance: Uniform material distribution increases fatigue life by 30% in cyclic load applications.

- Lower Post-Processing Costs: Elimination of internal voids reduces the need for expensive infiltration or welding repairs.

- Faster Assembly: Tighter tolerances (±0.05mm) reduce fit issues during component integration, cutting assembly time by 15%.

Integration and Handling Guidelines

Step 1: Receipt and Inspection Protocol

- Upon delivery, inspect packaging for damage—each aluminum die casting is packaged in anti-static trays with foam inserts to protect the spray coating.

- Verify quantity against packing list and check for visible defects (scratches, coating irregularities) using Figure 2 as a quality reference.

- For critical applications, conduct a quick dimensional check of key features using calibrated calipers (tolerance: ±0.05mm).

- Inspect flow channel vestiges (gate marks) for uniformity—this indicates proper sequential filling during production.

Step 2: Preparation for Assembly

- Clean components with a dry microfiber cloth to remove dust—avoid water or solvents that may damage the spray coating.

- If secondary machining is required (e.g., drilling, tapping):

- Use high-speed steel (HSS) or carbide tools with cutting fluid (aluminum-specific coolant).

- Maintain cutting speed of 100-300 m/min to prevent work hardening.

- For bonding applications, lightly abrade the coating in the bonding area with 320-grit sandpaper to improve adhesion—test on a sample first.

Step 3: Installation and Mounting

- Align the double-deck casting with mating components using guide pins (if applicable) to prevent cross-threading or misalignment stress.

- Use aluminum-compatible fasteners (e.g., grade 18-8 stainless steel) with appropriate torque settings:

- M4-M6 screws: 2-4 N·m

- M8-M10 screws: 5-8 N·m

- For sealed applications, apply a continuous bead of silicone sealant (temperature-rated for your operating range) along mating surfaces.

- Avoid using impact tools during installation, as sudden force may cause micro-cracks in complex areas.

Step 4: Maintenance and Long-Term Care

- Clean periodically with a mild detergent and soft brush—avoid high-pressure washing directly on the spray coating.

- Inspect annually for coating wear in high-friction areas—touch-up kits with matching spray paint are available upon request.

- Store unused components in a dry environment (relative humidity <60%) to prevent under-coating oxidation.

- For high-temperature applications (>80°C), apply a heat-resistant lubricant to moving contact points quarterly.

Application Scenarios

The unique capabilities of our aluminum die casting (Model L018516)—particularly its superior gas evacuation and structural uniformity—make it ideal for these critical applications:

1. Automotive Transmission Components

- Typical Use: Valve bodies, shift forks, and transmission housings.

- Why It Works: Sequential filling eliminates oil leakage paths (voids) that cause pressure loss. The double-deck design integrates multiple functions (fluid channels, mounting points) into a single component, reducing assembly complexity.

- Performance Benefit: Withstands 500,000+ cycles under 100+ bar hydraulic pressure without failure.

2. Industrial Hydraulic Manifolds

- Typical Use: Multi-port fluid distribution blocks for machinery.

- Why It Works: Uniform material density (no internal voids) ensures consistent pressure handling across all ports. The optimized flow channels in the casting mirror the hydraulic circuit, reducing pressure drop by 15%.

- Installation Advantage: Double-deck design allows for stacked circuit configurations, saving 40% of installation space.

3. Electronic Enclosures and Heat Sinks

- Typical Use: Enclosures for power inverters, motor controllers, and industrial PCBs.

- Why It Works: Aluminum’s thermal conductivity (160 W/m·K) combined with uniform wall thickness ensures efficient heat dissipation. The spray coating provides electrical insulation (10¹² Ω surface resistance) for safety.

- Design Flexibility: Multi-gate system enables complex internal ribbing for structural support without compromising heat transfer.

4. Heavy Machinery Structural Components

- Typical Use: Linkage brackets, pivot housings, and sensor mounting plates.

- Why It Works: Enhanced fatigue resistance from uniform grain structure prevents premature failure under cyclic loads. The 603.52g weight balances strength and portability for mobile equipment.

- Environmental Resistance: Spray coating withstands exposure to dirt, moisture, and temperature extremes in construction and agricultural environments.

Key Benefits for International采购商

- Lower Total Cost of Ownership: Reduced defect rates (2-3% vs. 8-12% industry average) cut scrap and rework costs by $0.75-$1.50 per unit. Faster assembly (15% time reduction) further lowers production expenses.

- Enhanced Product Reliability: Elimination of internal voids and gas pockets reduces field failures by 40% in critical applications like hydraulic systems and automotive components—minimizing warranty claims and brand damage.

- Design Freedom: Our multi-gate sequential filling technology enables complex geometries that would be impossible with standard casting methods, allowing采购商 to innovate product designs without manufacturability compromises.

- Consistent Quality Across Batches: Advanced process control ensures part-to-part uniformity (±0.05mm tolerance) even across 100,000+ unit production runs—critical for automated assembly lines.

- Faster Time to Market: 2-cavity production and optimized tooling reduce lead times to 4-6 weeks (vs. 8-10 weeks for competitors), helping采购商 meet tight launch deadlines.

- Regulatory Compliance: Products meet international standards (ASTM B85, ISO 9001, RoHS) for seamless market access in North America, Europe, and Asia—eliminating costly rework for regional requirements.

- Sustainability Benefits: Aluminum’s 100% recyclability combined with our near-net-shape casting process reduces material waste by 30% compared to machining from solid billets.

Certifications and Quality Compliance

Our aluminum die casting (Model L018516) and manufacturing processes adhere to the most stringent international standards, ensuring quality and regulatory acceptance worldwide:

- ISO 9001:2015: Comprehensive quality management system certification covering design, production, and testing processes.

- ASTM B85-20: Compliance with the leading standard for aluminum-alloy die castings, verifying material composition and mechanical properties.

- ISO 16949:2016: Automotive-specific quality certification (available for automotive采购商) ensuring compliance with IATF requirements.

- RoHS 2.0: Free of restricted substances (lead, mercury, cadmium, etc.) for sale in the European Union and global markets.

- REACH: Compliance with European chemical regulations, ensuring no SVHCs (Substances of Very High Concern) above threshold levels.

- NADCAP (Optional): Available for aerospace采购商 requiring special process certification for critical components.

Every shipment includes full documentation: material test reports (MTRs), dimensional inspection records, and certification copies to support your incoming quality control processes.

Customization Options

We understand that every application has unique requirements. Beyond our standard Model L018516, we offer extensive customization for our aluminum die castings:

1. Design and Geometry Customization

- Deck Configuration: Single, triple, or custom multi-deck designs to match your assembly space constraints.

- Cavity Number: 1, 3, or 4-cavity molds (1-cavity ideal for prototypes, 4-cavity for maximum volume production).

- Gate Configuration: Custom multi-gate layouts engineered for your specific part geometry, with sequential or simultaneous filling options.

- Integrated Features: Threaded inserts, O-ring grooves, fluid channels, and mounting bosses added during casting to eliminate secondary operations.

2. Material and Mechanical Properties

- Aluminum Alloys:

- A380: Standard (excellent castability, good strength)

- A383: Higher fluidity for complex thin-walled sections

- A413: Superior heat resistance for high-temperature applications

- Custom alloys: Tailored to specific tensile/elongation requirements

- Heat Treatment: T5 or T6 heat treatment to enhance strength (up to 300 MPa tensile strength) for high-load applications.

3. Surface Finish Options

- Coating Types:

- Anodizing: Clear, black, or colored (improved corrosion resistance, decorative)

- Powder Coating: Textured or smooth finishes in custom RAL/Pantone colors

- Electroplating: Nickel, chrome, or zinc plating for conductivity or wear resistance

- PTFE Coating: Low-friction surface for moving parts

- Surface Texturing: Custom patterns, knurling, or embossing for grip or aesthetic appeal.

- Branding: Laser engraving of logos, part numbers, or QR codes for traceability.

4. Quality and Testing Customization

- Inspection Levels: Enhanced sampling plans (e.g., 100% CMM inspection) for critical dimensions.

- Performance Testing: Pressure testing (up to 500 bar), leak testing (helium mass spectrometer), or fatigue testing.

- Packaging: Custom packaging solutions including anti-static trays, labeled cartons, or returnable dunnage with barcoding for your inventory system.

Our engineering team provides free design-for-manufacturability (DFM) analysis, helping optimize your aluminum casting for cost, quality, and performance before tooling begins.

Production Process and Quality Control

1. Manufacturing Workflow

- Design and Engineering:

- 3D modeling using SolidWorks/Creo with flow simulation (Moldflow) to optimize gate placement and flow channels.

- DFM analysis to identify potential filling issues and recommend design adjustments.

- Tooling design with integrated cooling channels and sequential gating controls.

- Tooling Fabrication:

- Mold base constructed from H13 tool steel (hardened to 48-52 HRC) for durability (500,000+ cycles).

- Precision machining of cavities and cores with ±0.005mm tolerance.

- Installation of sequential gate control system for multi-gate synchronization.

- Material Preparation:

- Aluminum alloy ingots melted in gas-fired furnace at 650-700°C.

- Degassing with nitrogen to remove hydrogen (≤0.15 cc/100g) and filtration to remove impurities >50μm.

- Alloy composition verification using optical emission spectroscopy (OES).

- Cold Chamber Die Casting:

- Molten aluminum injected into mold at 80-120 MPa pressure with 2-5 m/s injection speed.

- Sequential gate activation controlled by computer to ensure proper filling order.

- Precision cooling (30-60 second cycle time) to control solidification and minimize internal stresses.

- Robotic part extraction to prevent deformation and ensure consistent cycle times.

- Trimming and Finishing:

- Automated trimming press removes sprue, runners, and flash.

- Robotic deburring to achieve Ra ≤ 1.6μm surface finish on critical edges.

- Visual inspection for surface defects and dimensional checks.

- Surface Coating:

- Pre-treatment (degreasing, etching) to ensure coating adhesion.

- Spray coating application (electrostatic for uniform coverage) followed by curing at 180°C for 30 minutes.

- Coating thickness and adhesion testing (ASTM D3359 cross-cut method).

- Final Inspection and Packaging:

- 100% visual inspection and sampling (10%) for dimensional verification via CMM.

- Pressure testing (if applicable) to verify leak tightness.

- Packaging in anti-static trays with desiccants to prevent moisture damage during shipping.

2. Quality Control Measures

- In-Process Monitoring:

- Real-time monitoring of melt temperature, injection pressure, and cycle time with automatic alerts for deviations.

- Statistical Process Control (SPC) with X-R charts for critical dimensions, updated hourly.

- First Article Inspection (FAI) for each production run, comparing results to design specifications.

- Advanced Testing:

- Ultrasonic testing to detect internal voids or cracks (especially in thick sections).

- Microstructure analysis (1 sample per 10,000 units) to verify grain structure and identify potential issues.

- Tensile testing of sample castings to confirm mechanical properties meet ASTM standards.

- Traceability System:

- Each casting marked with a unique batch code linking to raw material certificates, production parameters, and inspection results.

- Digital records retained for 10 years, enabling full traceability for quality audits or field issue investigations.

Customer Testimonials

“The sequential filling technology in these aluminum die castings solved our biggest quality issue—internal voids causing hydraulic manifold leaks. Our field failure rate dropped from 8% to less than 1% after switching to Model L018516. The 2-cavity production also cut our lead time by 3 weeks.”

— Heinrich Schmidt, Quality Director, Industrial Hydraulics GmbH (Germany)

“As an automotive supplier, we need components that meet strict IATF standards. These aluminum castings consistently pass our rigorous leak testing and dimensional checks. The spray coating has also proven durable in our 500-hour salt spray tests—critical for undercarriage components.”

— Maria Rodriguez, Procurement Manager, AutoComponents Inc. (USA)

“The double-deck design of Model L018516 allowed us to reduce our electronic enclosure part count from 3 to 1, simplifying our supply chain and cutting assembly time by 40%. The uniform wall thickness also improved heat dissipation—our thermal simulations showed a 12°C reduction in operating temperature.”

— Takeshi Tanaka, Engineering Manager, TechEnclosures Japan (Tokyo)

Frequently Asked Questions (FAQ)

Q1: What is the minimum order quantity (MOQ) for Model L018516?

A1: The standard MOQ is 4,000 pieces. For prototype or small-batch orders (50-1,000 pieces), please contact our sales team—we offer flexible terms for new customers or custom projects, including expedited prototype services.

Q2: How does sequential filling differ from conventional multi-gate filling?

A2: Conventional multi-gate systems often fill simultaneously, creating flow fronts that collide and trap gas (interval filling). Our sequential filling activates gates in a controlled order, with each gate’s flow “pushing” air toward vents rather than trapping it. Aluminum castings This eliminates internal voids and ensures uniform material density—critical for pressure-containing applications like hydraulic manifolds.

Q3: Can you adjust the flow channel design for our specific part geometry?

A3: Absolutely. Our engineering team specializes in custom flow channel design. We use advanced flow simulation software to optimize gate placement, runner dimensions, and filling sequence for your unique part geometry. This service is included with custom tooling orders, and we provide detailed simulation reports for your approval before production begins.

Q4: What is the lead time for standard and custom orders?

A4:

- Standard Model L018516: 4-6 weeks from order confirmation.

- Custom modifications to existing tooling (e.g., surface finish, minor design changes): 6-8 weeks.

- Fully custom aluminum die castings (new tooling required): 12-16 weeks (includes design, simulation, tooling fabrication, and testing).

Rush options are available for an additional fee, reducing lead times by 30-40%.

Q5: How do you ensure consistent quality across large production runs?

A5: We implement a multi-layer quality control system:

- Real-time process monitoring with automated alerts for temperature, pressure, or cycle time deviations.

- Statistical Process Control (SPC) with hourly sampling and X-R chart analysis for critical dimensions.

- Periodic destructive testing (tensile, microstructure) to verify material properties remain within specification.

- Final inspection using automated vision systems for surface defects, complemented by CMM sampling for dimensional accuracy.

For orders over 50,000 units, we provide a process capability study (Cpk ≥ 1.33) for critical features.

Q6: What payment terms and shipping options are available?

A6:

- Payment: T/T (30% deposit upon order confirmation, 70% balance before shipment). Irrevocable L/C at sight is available for orders over $100,000.

- Incoterms: FOB, CFR, CIF, FCA (Ningbo or Shanghai ports).

- Shipping: Ocean (most cost-effective for large orders), air (3-5 days for urgent needs), or land (for regional Asian markets).

We work with major freight forwarders and can coordinate door-to-door delivery if required.

Q7: What warranty do you offer, and how are claims handled?

A7: We provide a 12-month warranty against manufacturing defects (porosity beyond specification, dimensional non-conformance, coating failure). For warranty claims:

- Notify us within 5 business days of discovering the issue, providing photos and batch codes.

- Our quality team will conduct a root cause analysis (typically within 3 business days).

- We will replace defective parts at no cost or issue a proportional refund—your choice.

- For critical production line interruptions, we offer expedited replacement shipping at our expense.

Our warranty claim resolution rate is 100%, with average resolution time of 5 business days.

Q8: Do you provide samples for testing before placing a large order?

A8: Yes. We can produce 5-10 prototype samples for your testing and validation. For standard Model L018516, samples are available within 2 weeks. For custom designs, samples are typically ready in 4-6 weeks (includes tooling modification or soft tooling). Sample costs are refundable if you proceed with a production order of ≥4,000 pieces.

Order and Shipping Information

1. Order Process

- Submit inquiry: Provide quantity, specifications, and customization requirements via email, website form, or phone.

- Receive quote: Detailed proposal with pricing, technical specifications, and lead time within 2 business days.

- Sample approval (optional): Evaluate 5-10 samples for fit, form, and function (with full inspection reports).

- Order confirmation: Sign proforma invoice and pay 30% deposit to initiate production.

- Production updates: Weekly progress reports with photos of in-process parts and quality checks.

- Pre-shipment inspection: Review final quality report (including dimensional data and test results).

- Final payment and shipment: Pay 70% balance, and we arrange shipping with tracking information provided.

2. Shipping Details

- Departure Ports: Ningbo and Shanghai (major international ports with daily sailings to all global destinations).

- Transit Times (Ocean Freight):

- North America (West Coast): 18-22 days

- North America (East Coast): 28-32 days

- Europe (Rotterdam/Hamburg): 28-35 days

- Southeast Asia: 7-12 days

- Australia: 18-25 days

- Air Freight: 3-5 days to major international airports, with door-to-door delivery available.

- Packaging: Standard packaging is anti-static trays in seaworthy cartons (20 pieces per carton). Custom pallets, crates, or returnable packaging available upon request.

- Documentation: Commercial invoice, packing list, certificate of origin, material test reports, and relevant certifications included with each shipment.

Our team speaks English, German, Spanish, and Mandarin, with 24/7 availability for urgent inquiries.